All items

Article: 2810/1

S2 Profi milling machine

With the new S2 Profi, we succeeded in combining high quality and practical parts with a compact and state-of-the-art design

S3 Premium milling machine

The new milling spindle with high-performance electronics allows speeds of up to 80,000 rpm and opens up to the user more processing options without complex conversion of the device or compromises in performance.

S3 Master milling machine

Beside the newest technical standard, the ergonomics are in the focus of the S3 Master. Optimal milling results are achieved by relaxed and stress free working.

S W1 electric spindle

Beside the newest technical standard, the ergonomics are in the focus of the S3 Master. Optimal milling results are achieved by relaxed and stress free working.

S Ceramic The ceramic milling kit

With the special ceramic milling set, Schick's milling machines can be retrofitted quickly and easily for the wet grinding of ceramics. This set can also be used for milling machines from other manufacturers.

Article: 2470/5

Suction tub with nozzle

For the processing of high-performance ceramics under water cooling, a special suction tub has been developed, which can be used directly at the work table or at every commercially available milling machine.

Article: 2805

S1 Basic unit

A compact basic unit specially developed for the rework of ceramic materials.

Article: 2498

Collection tub without nozzle

For the processing of high-performance ceramics under water cooling, a special suction tub has been developed, which can be used directly at the work table or at every commercially available milling machine.

Article: 2655

Separator

The special separator is positioned between the suction tub and the usual laboratory suction and serves to separate water from air. This keeps the laboratory suction filter dry.

Article: 2640/1

Turbine T100

Powerful turbine with water spray for use in the milling machine or hand-guided. 300,000 rpm and 1.4 L spray water tank. Fully adjustable.

Article: 2480/1

Power supply for LED light head

Power supply for LED light head 2510 and 2510/1 when using with the S1 Basic/Junior or competitor milling machines.

Article: 2660

Diamond tool set for turbine

Diamond tool set with FG shank for working through sintered zircon with the turbine. 0 °, 1 ° and 2 ° diamonds respectively in rough and fine for pre-grinding and finishing.

Article: 2665

Polishing set 2.35 mm

Special three-stage polishing set with 2.35 mm shank for perfect polishing of zirconium telescopes.

Article: 2481

Adapter for turbine T100

Adapter specially for the T100 turbine handpiece. Inner dimensions: 18 mm, outer dimensions: 22 mm. Fits all current Schick milling machines with a 22 mm pick-up diameter.

Article: 2481/1

Adapter for Turbine AquaPresto

Adapter for the AquaPresto turbine handpiece. Inner diameter: 15,65 mm. Outer diameter: 22 mm. Fits to all current Schick milling machines.

Article: 2481/6

Adapter-sleeve for F1

Adapter especially for fitting the T100 handpiece to the Degussa F1 milling machine.

SHERAeasy-model CAD software for dental technology

CAD software for dental technology. The new model builder software SHERAeasy-model: design high-precision models with just a few clicks.

Digi E Mill 5

Neither an external compressed air connection is required for the Digi E Mill5, nor a built-in compressor is needed. This is made possible by the AIRTOOL, which has also been filed for patent. The turbine blades of the AIRTOOL generate high speeds that ar

digi MILL4 wet+

5 simultaneously functioning axes air pressure (min./max.): 7 bar/ 8 bar (recommended 7 bar) automatic tool changer for 16 tools user friendly CAM software all open STL-files can be used

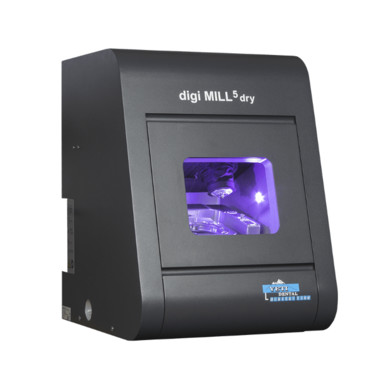

digi MILL5 Dry

5 simultaneously functioning axes air pressure (min./max.): 7 bar/ 8 bar (recommended 7 bar) automatic tool changer for 16 tools user friendly CAM software all open STL-files can be used