Milling Technology

Milling Technology

Digi E Mill 3

The new Digi E Mill 3 enables you to automate the precision trimming of occlusal appliances. You can expect the very best results in the shortest time with no arduous reworking. The machined fabrication also ensures a consistently high quality.

Digi E Mill 4

The new Digi E Mill 3 enables you to automate the precision trimming of occlusal appliances. You can expect the very best results in the shortest time with no arduous reworking. The machined fabrication also ensures a consistently high quality.

Digi E Mill 5

Neither an external compressed air connection is required for the Digi E Mill5, nor a built-in compressor is needed. This is made possible by the AIRTOOL, which has also been filed for patent. The turbine blades of the AIRTOOL generate high speeds that ar

digi MILL4 wet+

5 simultaneously functioning axes air pressure (min./max.): 7 bar/ 8 bar (recommended 7 bar) automatic tool changer for 16 tools user friendly CAM software all open STL-files can be used

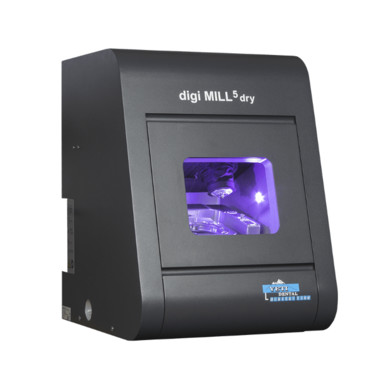

digi MILL5 Dry

5 simultaneously functioning axes air pressure (min./max.): 7 bar/ 8 bar (recommended 7 bar) automatic tool changer for 16 tools user friendly CAM software all open STL-files can be used